Hardness and Tensile Strength Analysis

A laboratory report on Spiralbanding

This is an excerpt from a wider analysis performed on various application types. For more details please contact us.

Microhardness Testing Details

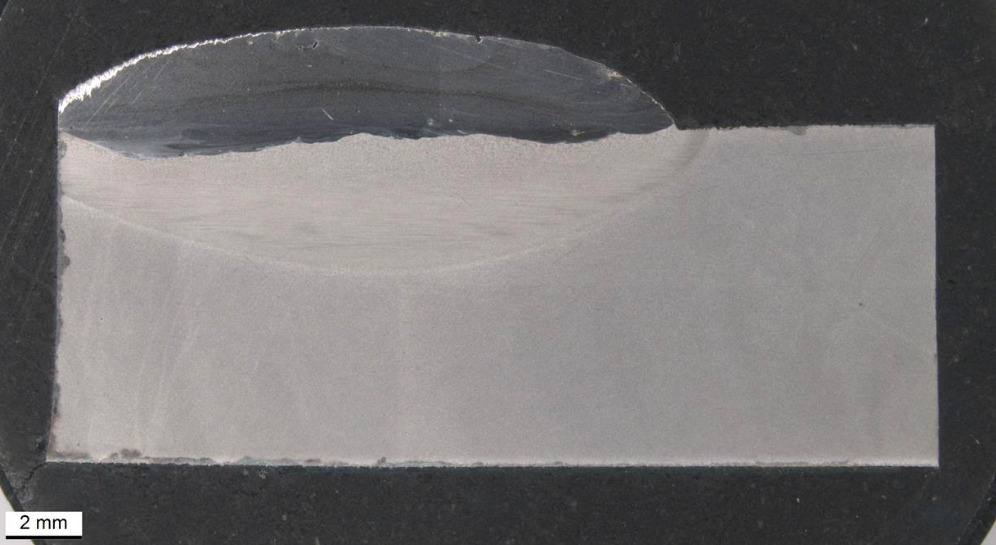

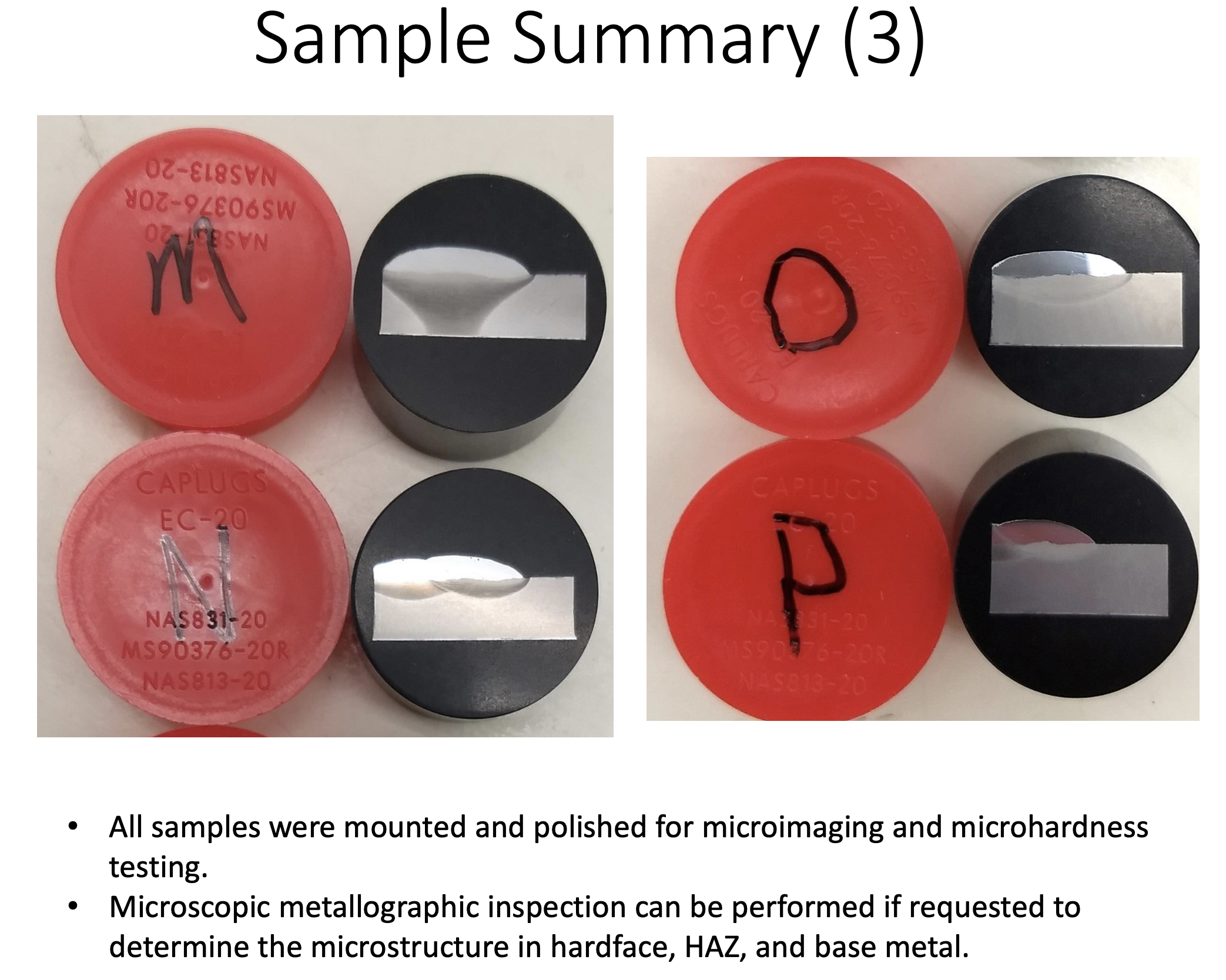

• Microhardness traverse measurements were performed on mounted and polished specimens as described below.

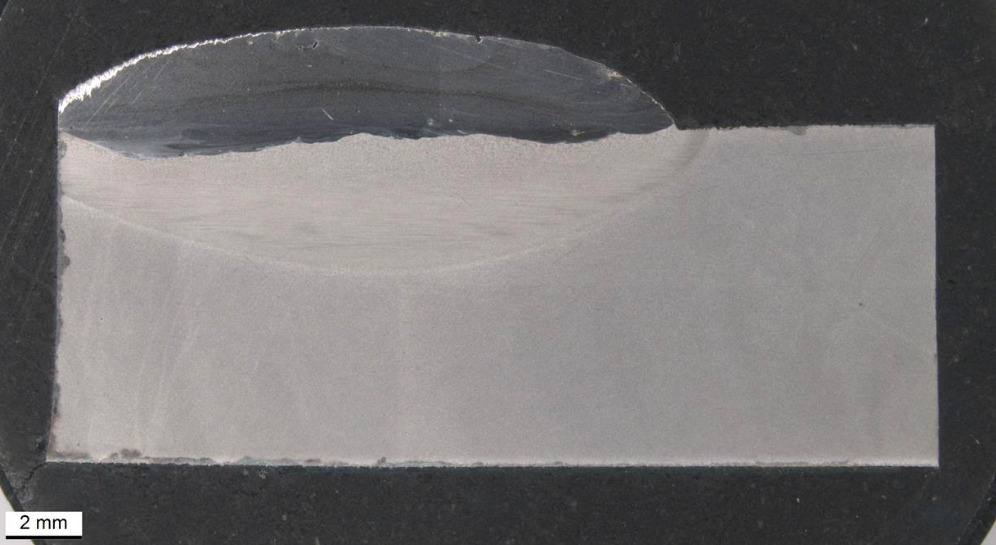

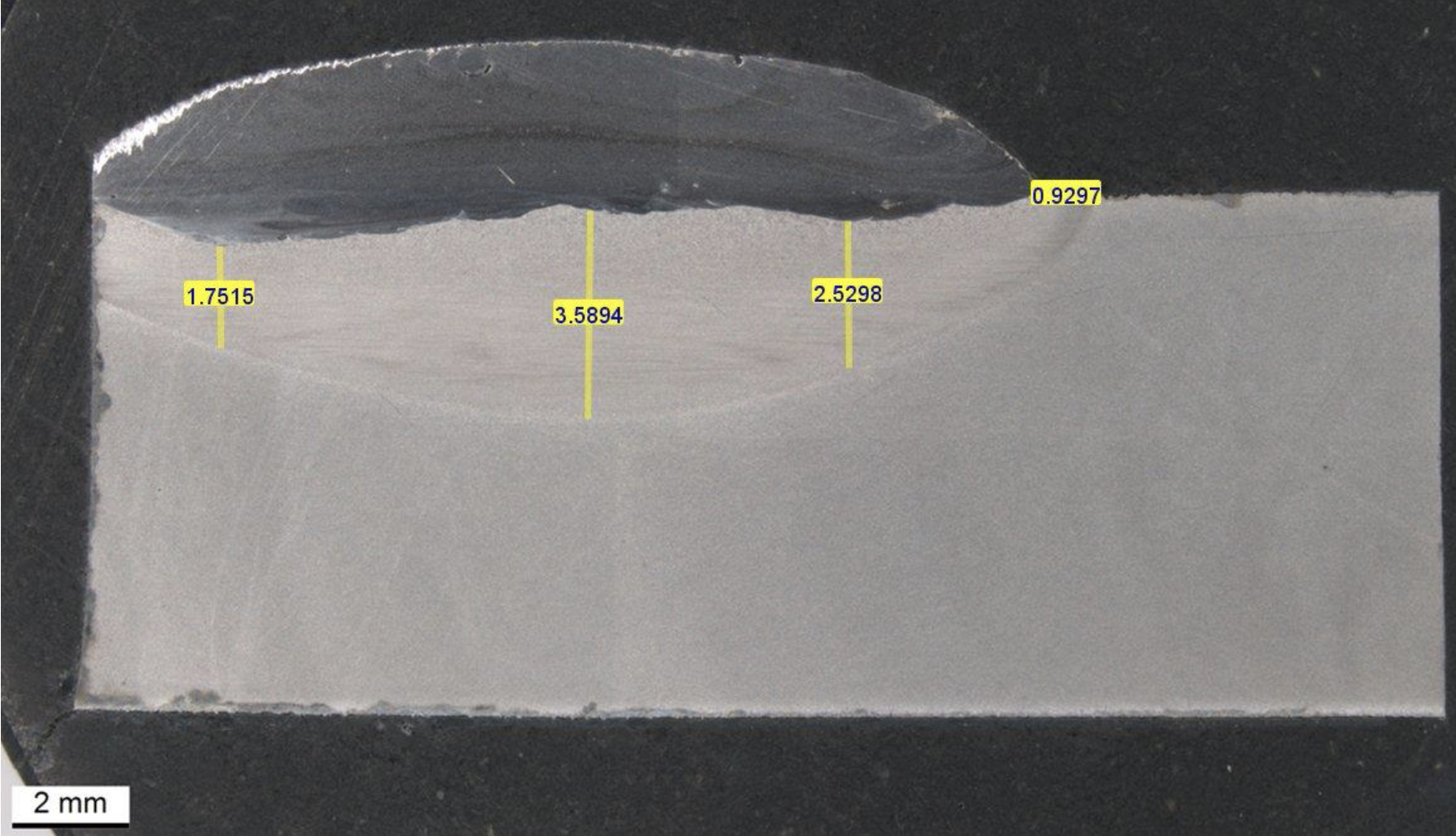

• Each microhardness region labeled on the subsequent pages indicates regions where material was excised for microhardness traverse evaluation. Ultimately, a cross-section was obtained in a direction perpendicular to the welding direction (parallel to the longitudinal direction of the pipe). See below.

Total hardness traverse regions = 4 welds (hardbandings)

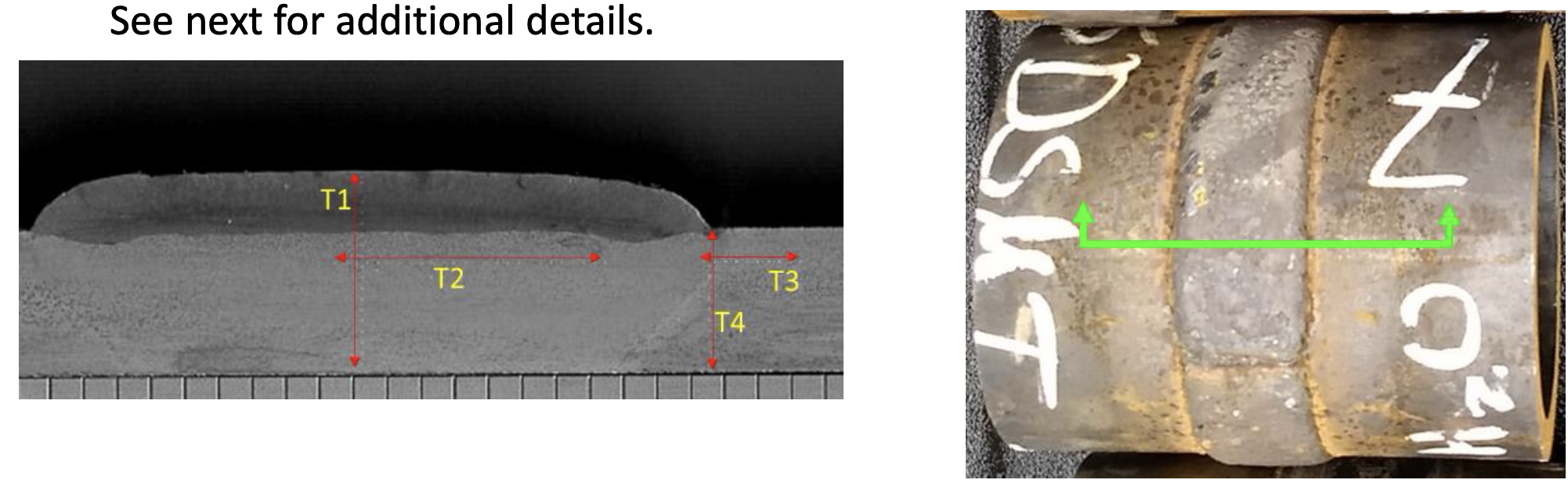

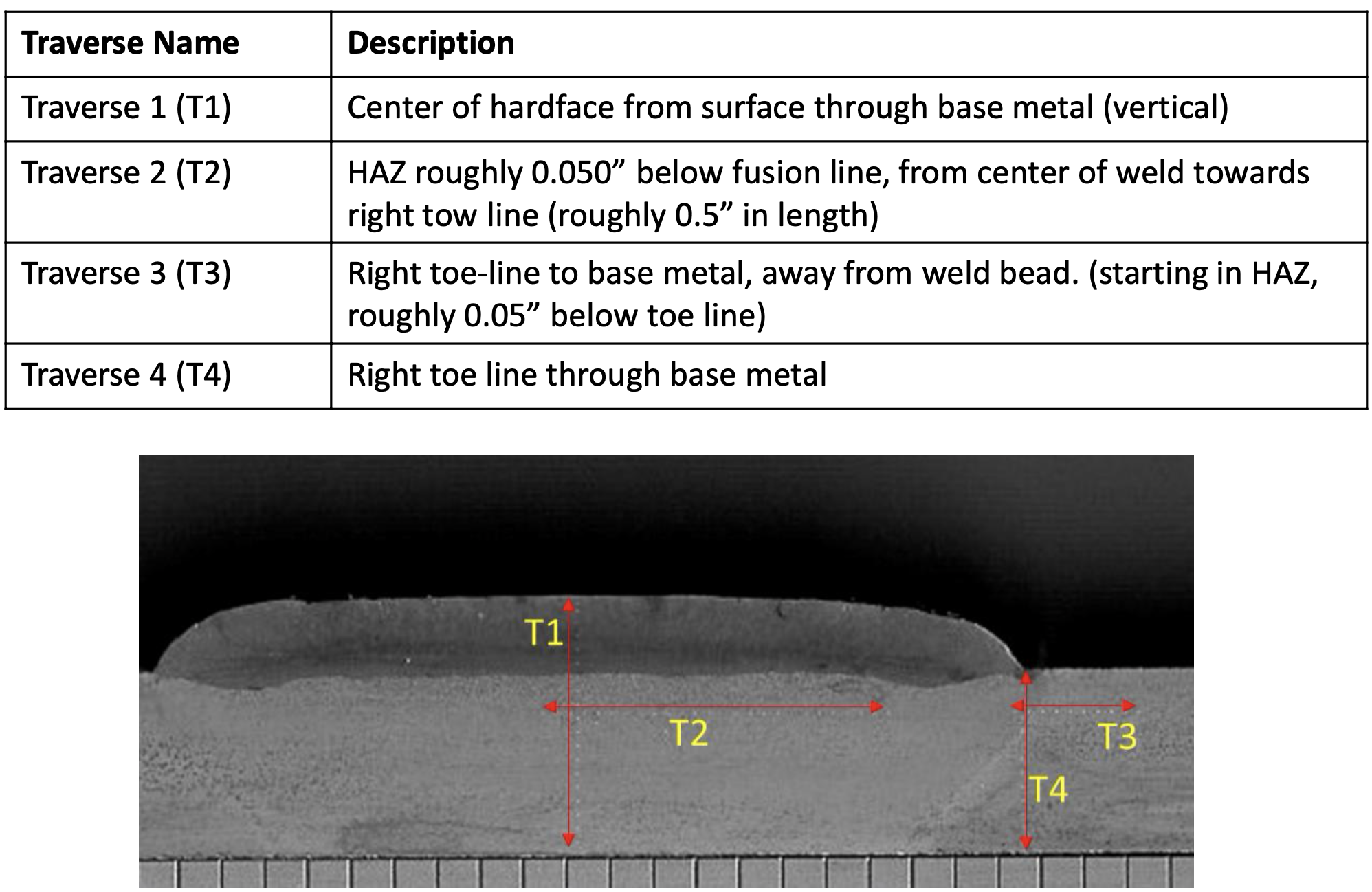

Each weld was characterized by performing 4 microhardness traverses as described below.

Thus, total hardness traverses = 4 welds x 4 traverses = 16 traverse measurements.

Microhardness Details

Four microhardness traverses was conducted on each specimen as described below.

- HAZ depth at centerline is ~3.6 mm (0.141 in)

- HAZ width at toe line is ~0.93 mm (0.037 in)

Tensile Testing

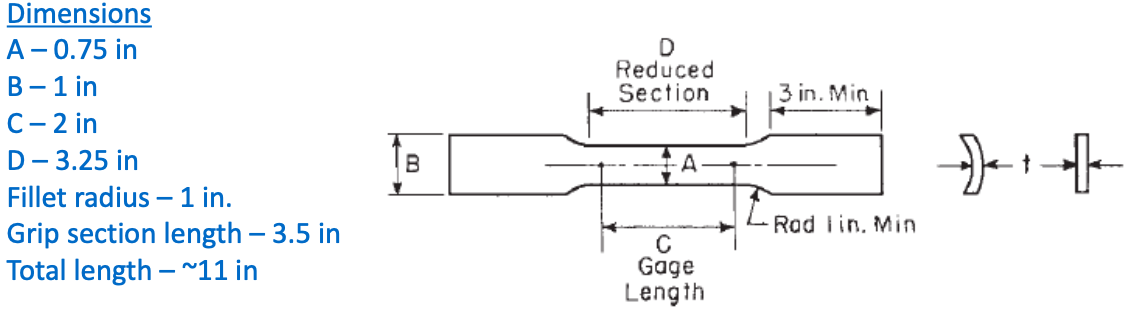

- Tensile testing was conducted per ASTM E8 and ASTM E370.

- Specimens were machined per the dimensions outlined below. Each specimen was machined such that the hardband region was located in the center of the reduced section and oriented at roughly 30 degrees to the loading direction.

- Each specimen was tested at a testing speed of 0.175 in/min and load and displacement were recorded.

- Ultimate tensile strength (UTS), yield strength (YS), percent elongation (%EL) were calculated and are summarized on subsequent pages.

- Detailed specimen measurements were performed before and after testing to determine the true cross-sectional area and calculate the UTS and YS.

Total tensile tests = 41 (4 base metal, 37 hardbanding regions)

All specimens failed in a ductile fashion outside the hardface region.