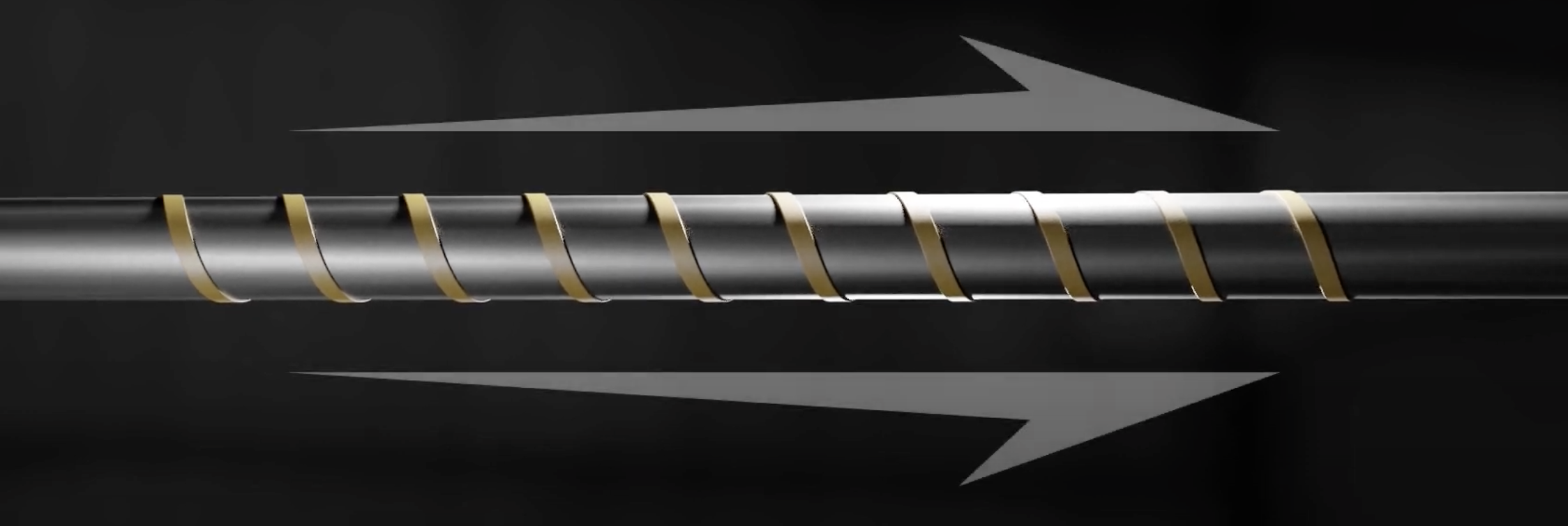

Spiralbanding Can Help Save Significant Drilling Costs

With Spiralbanding, drill pipe is in the well longer without being rotated top to bottom or replaced, increasing productivity. The cost savings associated with replacing drill pipe less often, and overall increased performance from the drill string are significant.

Learn More

Additional Benefits

During testing it was discovered Spiralbanding with Spiralband NC actually stiffens the center of the drill pipe body, reducing deflection of the drill pipe that can translate to less drag and allow more weight on bit.

Learn More

Spiralband® NC

Postle's Spiralbanding NC is designed for extreme abrasion resistance, and is always applied 100% crack-free.

Learn More

Spiralbanding is Safe and Reliable: Let Us Prove It To You

Postle Industries began trialling our patented Spiralbanding Technology in 2017. We have performed a catalogue of laboratory and down-hole testing to prove its reliability. Protected by US 11,286,728.

Learn MoreSkyeSpiral Equipment

We have used our experience in automated welding equipment to design 'SkyeSpiral', a machine that makes the application of Spiralbanding consistent and reliable.

Learn MoreInterested In Spiralbanding?

Postle trains and licenses service companies on Spiralbanding wherever there is demand around the world. For a current list of companies who are approved, and to explore how your organization can benefit from Spiralbanding please contact us.

Contact Us